At HTT Inc., we’re a dedicated full-service metal stamping company committed to providing the best experience and results for our customers. Our specialty in deep draw stampings pairs with our versatile skillsets to ensure your needs are met at every stage and the highest quality standards are upheld. We use the latest machinery to produce precise metal parts even more rapidly and accurately, and our expert team offers decades of experience serving customers from a wide array of industries. With HTT, you can count on superior precision metal stamping services tailored to your needs and always exceeding your expectations.

Learn more about our comprehensive metal stamping services and what makes HTT the ideal partner for your next project. Ready to discuss your next project? Contact us today.

The value of partnering with HTT is the promise of completing your project under one roof so you can save time and money by leveraging our turnkey services. Pair our specialized stamping support with our additional services to maximize their benefits for your products and enjoy even better results.

We have more than 44 presses dedicated to delivering high-quality, medium-to-high-volume metal stampings to customers across a range of industries.

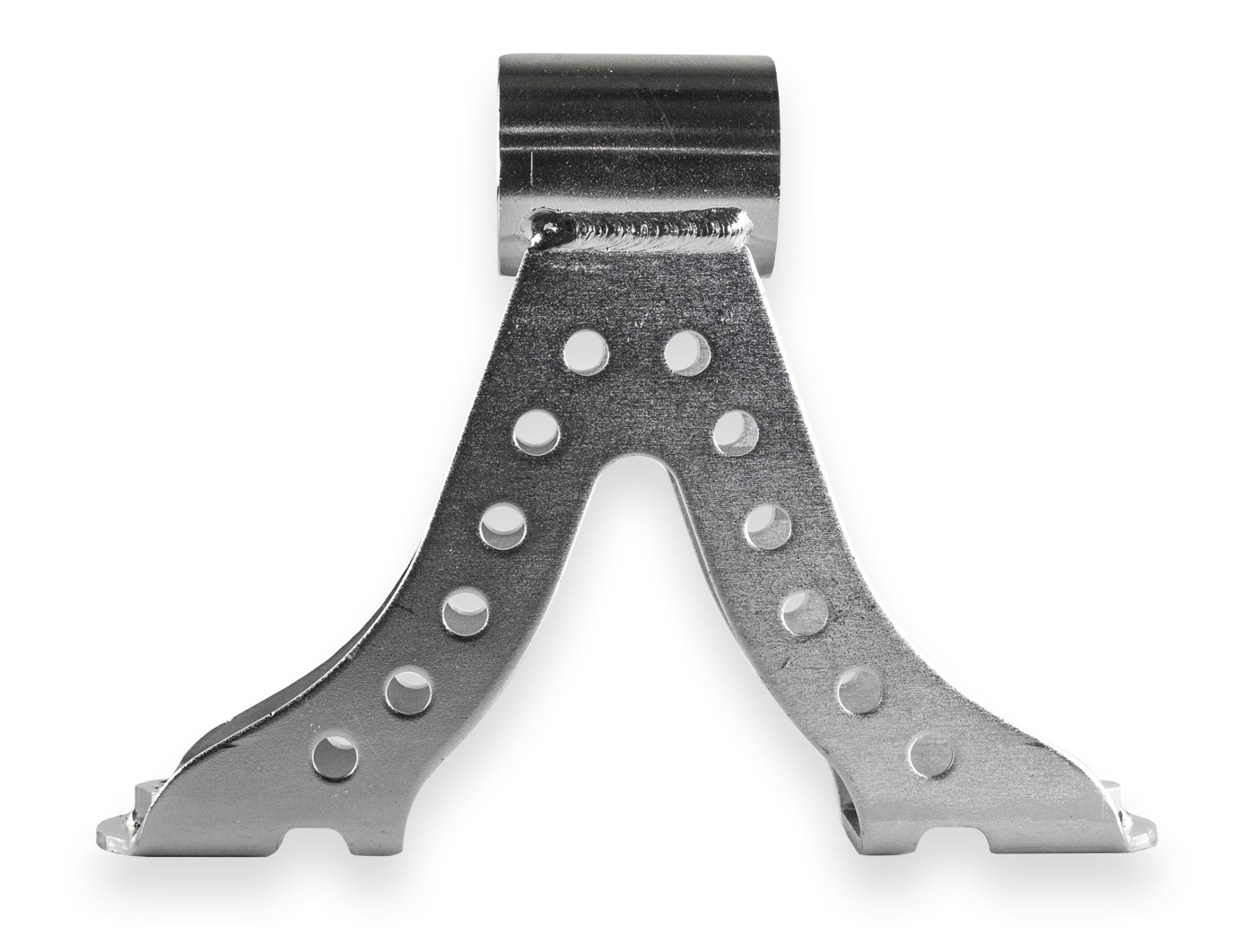

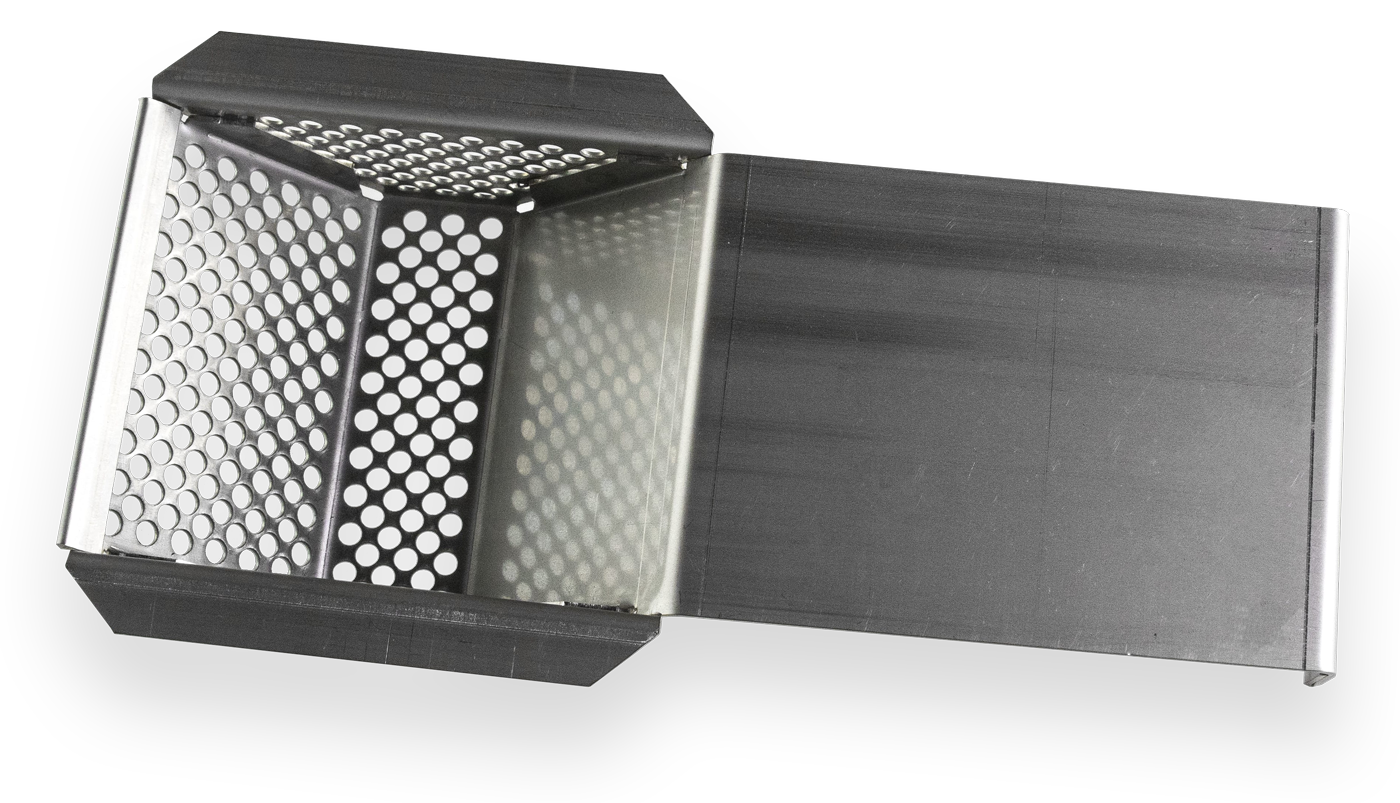

We specialize in deep draw metal stamping so you can achieve complex geometries more accurately and rapidly with less material waste.

Leverage our robotic welding assistance to push forward on your project without delay.

Our tooling and die support is essential for customers taking their concept to full production.

Our advanced powder coating will clean and complete your project to your precise finishing requirements — and level up its lifespan.

We offer value-packed metal fabrication support to customers in need.

Seeking a reliable wire EDM partner for your custom metal parts? We can handle it and much more, all under one roof.

Since 1985, HTT has carried the same commitment to quality products and excellent services. Contact us today to leverage our advanced metal stamping support to level up your products and experience.