A leading company in the water treatment space, renowned for its expertise in aeration products and biological systems, recently faced a series of challenges threatening its efficiency and cost-effectiveness. These challenges were critical to maintaining their competitive edge in a rapidly evolving industry.

Customer Challenges

The company encountered some critical obstacles highlighted below:

- Reliable On-Time Delivery: Ensuring the prompt delivery of specific metal-stamped aeration system parts to maintain uninterrupted operations was a significant challenge. Delays in receiving these parts could lead to costly downtime and disrupt the production schedule.

- Increased Capacity and Volume: With a growing client base and increasing demand for their products, the company needed to expand its production capacity. This required scaling up operations and ensuring that the products’ quality and consistency were maintained.

- Decreased Cost: To remain competitive, the company needed to lower its production costs. This involved finding ways to reduce costs without compromising on quality or efficiency.

Solution

To address these challenges, the company partnered with HTT, a leading provider of metal-stamped parts known for its innovative solutions and value-added services. HTT implemented a series of strategic changes to enhance the company’s operations:

- Supplier Transition: HTT transitioned the company to a more dependable and efficient source for metal-stamped parts. This transition improved supply chain reliability, ensuring that parts were delivered on time and met the required quality standards.

- Supply Chain Reduction: HTT streamlined the supply chain by consolidating processes such as stamping, laser/press-brake, and welding/assembly under one roof. This consolidation reduced the complexity of the supply chain, minimized potential delays, and leveraged HTT’s value proposition of integrated services.

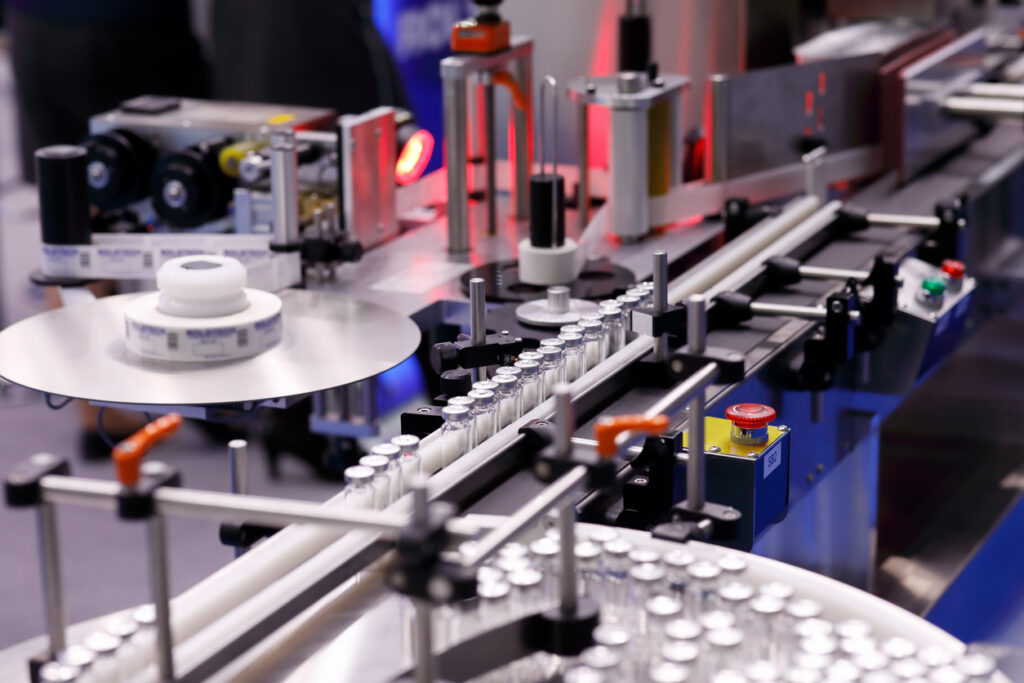

- Automation Integration: HTT collaborated with their in-house automation resources to explore and implement technologies that could drive cost savings and boost production efficiency. This included the integration of automated systems for parts handling and assembly, which reduced manual labor and increased throughput.

Results

The adoption of these solutions yielded significant positive outcomes:

- Cost Reduction: The company achieved a substantial decrease in operational production costs. While the exact percentage reduction was not disclosed, it is evident that the strategic supply chain and automation improvements implemented played a significant role in driving these efficiencies.

- Enhanced Delivery Reliability: The reliability of on-time deliveries demonstrated a marked improvement, ensuring seamless operations and higher client satisfaction. This improvement was quantified through a reliability assessment, which showed a marked increase in delivery performance.

- Increased Capacity: The company successfully scaled up its production capacity to meet the increasing demands of its clients. This expansion was supported by investments in additional production space and advanced technologies, leading to accelerated revenue growth.

Lessons Learned

- Culture Drives Focus for On-Time Delivery: Cultivating a strong organizational culture focused on punctual delivery is crucial. By drawing on experience from working with time-sensitive industries, the company emphasized the importance of meeting deadlines consistently.

- Consolidating Vendors and Reducing Overall Supply Chain Saves Money: The case demonstrated that consolidating vendors and streamlining the supply chain can lead to significant cost savings and operational efficiencies.

By strategically managing vendors, reducing the supply chain, and incorporating automation, HTT helped the customer not only address its sourcing challenges but also position itself as a more efficient and cost-effective partner in the industry. HTT’s ability to integrate specific metal-stamped parts with ancillary value-added services offers tangible value for its customers.