Maximizing supply chain efficiency is invaluable to the success of your project, and selecting the right custom metal stamping partner can significantly impact this efficiency. It’s important to consider the right approach for your specific product needs, because the choice of manufacturing partner can make or break your project. Let’s take a closer look at the value turnkey metal stamping can bring and how HTT can improve the quality of your products.

The Benefits of Turnkey Custom Metal Stamping

End-to-end services can benefit your project in a variety of key ways. When partnering with a turnkey manufacturer, your metal stamper has full control over production, which means they can oversee and correct any problems that may occur. With more collaboration between the design and production teams, which are both in-house, you can also expect higher-quality finished products. In addition, turnkey custom metal stamping results in faster turnaround times, with no unnecessary shipping delays that could derail your entire project.

When working with multiple vendors, on the other hand, your metal stamping partner has less control over quality and the production schedule, which means there is more of a risk of supply chain delays, as well as communication issues. This ultimately results in higher long-term costs due to added material waste and delays.

Now that you understand that quality is non-negotiable when it comes to turnkey metal stamping, there’s only one choice of manufacturing partner: HTT.

How HTT’s Start-to-Finish Support Improves Quality and Boosts Your Competitive Advantage

Since 1985, HTT has been dedicated to streamlining production for our customers, and in the process, improving both quality and affordability. We offer end-to-end support, helping our customers throughout each stage of production, from concept to creation. With our turnkey custom metal stamping capabilities, we cut out the middleman and simplify the supply chain, prioritizing efficiency and optimizing costs at every turn.

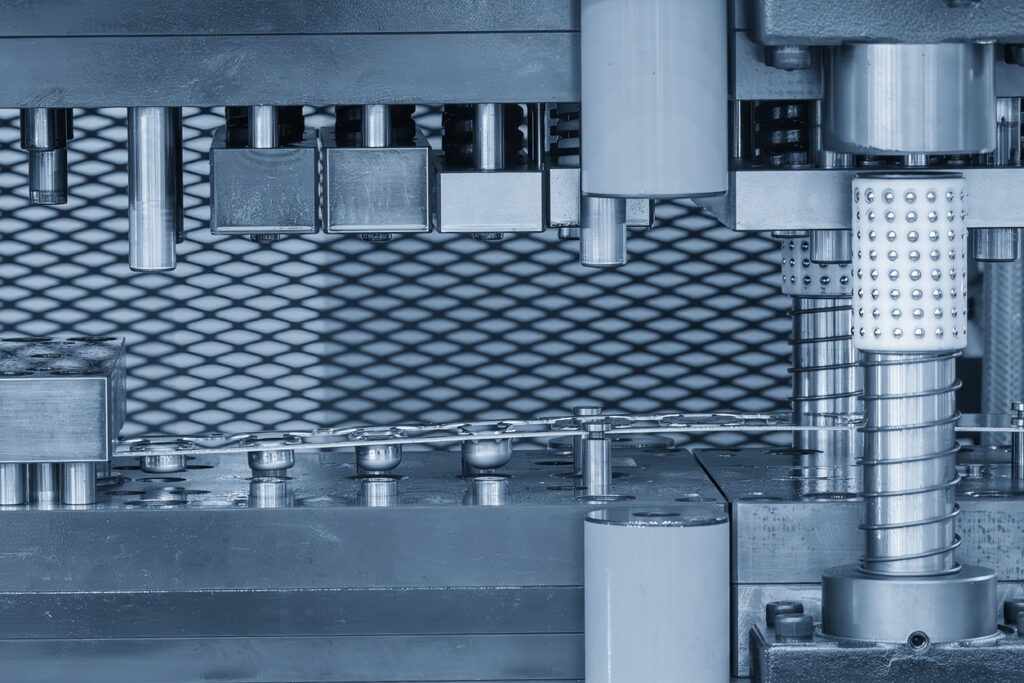

We bring our expertise to the very beginning of production, offering upfront design consultations that allow us to perfect your product’s design and bring your vision to life. Our capabilities include metal stamping, deep drawn stamping, metal fabrication, and more, and our secondary processes include powder coating and other invaluable services that extend the longevity of your components while boosting their aesthetics.

At HTT, we pride ourselves on solving problems for our customers. For example, one of our valued customers was facing significant quality issues after sourcing components from an international metal stamping manufacturer. Added to inventory delays due to shipping and increased costs, the customer’s operational efficiency suffered. Luckily, they decided to partner with HTT and we got right to work improving product outcomes.

First, our engineering team collaborated closely with the customer, conducting a thorough evaluation of each part to identify the defects. We then retooled the parts, boosting dimensional control of the features and resolving the customer’s painpoints. Because of our partnership, our customer experienced improved product quality, more reliable part performance, reduced lead times, improved supply chain efficiency and significant cost savings.

Our end-to-end custom metal stamping solutions allows us to work closely with customers to identify and solve manufacturing challenges, optimizing costs and quality in the process. With HTT’s start-to-finish capabilities, you can rest assured knowing that your expectations will be exceeded. Connect with HTT today to maximize the value of your next project.