In the manufacturing world, there is a constant pressure to innovate, cut costs, and maintain quality. There are a lot of different so-called experts competing to be the answer to this problem, but few can do it all — from initial concept to full production and beyond. Turnkey metal stamping solutions can streamline manufacturing time, enhancing value and reducing overall costs in the process. Let’s explore the benefits of turnkey metal stamping services and how HTT can simplify manufacturing workflows from start to finish.

Modern Manufacturing Challenges

As both product design and the production process become increasingly more complex, expect more manufacturing challenges to spring up. This is especially true when working across multiple vendors and suppliers, which often results in quality and consistency concerns.

In such a competitive environment, there is also a growing need to accelerate time-to-market, which is difficult when waiting for different suppliers. This can lead to unnecessary cost constraints that impact the ultimate success of your project. Relying on multiple vendors can lead to expensive, time-consuming challenges that can derail your project. Partnering with a turnkey metal stamper is the solution.

Streamlining Manufacturing with Turnkey Metal Stamping Solutions

When you partner with a turnkey metal stamping manufacturer, you save time across the entire project lifecycle. With single-point project management, you can expect fewer delays and no time wasted waiting to hand off the project to an additional vendor. Rapid prototyping evaluates designs faster and turnkey metal stamping services reduce lead time.

In addition to improved timelines, you can also expect enhanced product quality when you choose turnkey metal stamping solutions. Upfront design consultations improve overall performance and manufacturability, prioritizing quality from the very beginning. Turnkey manufacturers utilize thorough quality control processes, and without the need for multiple vendors, you can also expect more consistency in production.

Consolidated services result in reduced costs as well because of lower labor and setup costs. Reduced reworks or extra materials also lower costs, and turnkey metal stamping solutions eliminate extra shipping or logistics expenses from multiple vendors.

HTT Can Perfect Your Project From Concept to Production

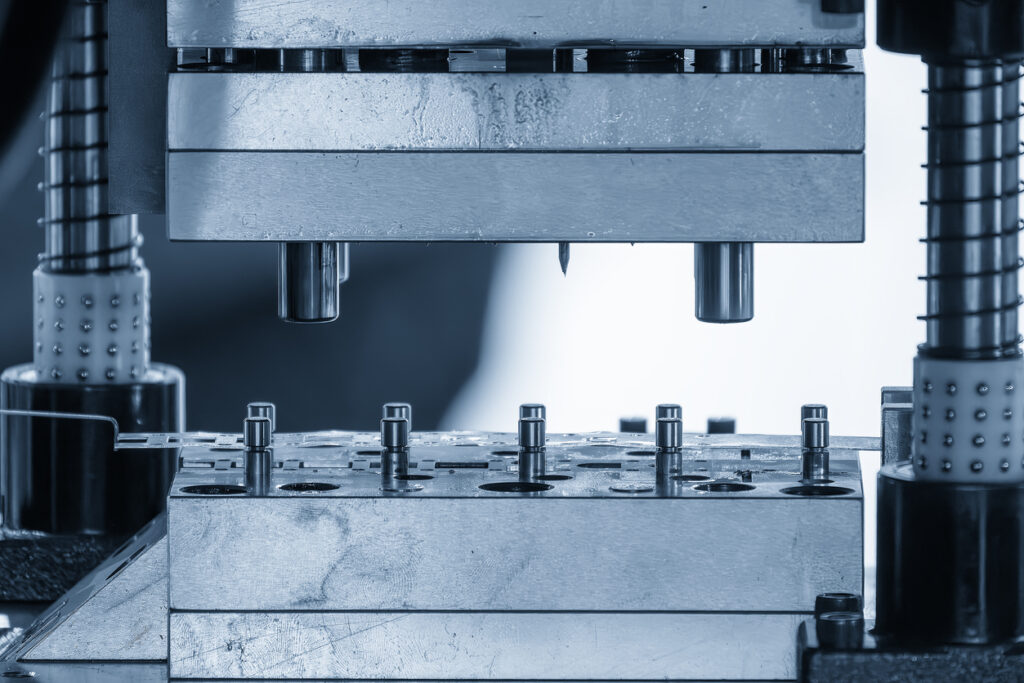

HTT is the ideal partner for custom metal stamping solutions that will save you time and money, while optimizing quality. We offer turnkey support that will take your metal stamped component from start to finish. It begins with design, ensuring that each aspect of the project can be manufactured accurately and in the most cost-effective manner. Prototypes then must be evaluated to guarantee performance and functionality before the project can move forward to production. We then ensure each component is completed to perfection with expert finishing and assembly services that match our customer’s precise specifications.

When you choose HTT, you are choosing a turnkey metal stamping partner with decades of experience providing excellence for customers from a variety of industries. We offer a full suite of comprehensive services under one roof, including design consultations, metal stamping services, deep drawn stamping, powder coating, and much more. Our end-to-end support and custom solutions are tailored to your industry, and our dedicated team members are able to execute logistics seamlessly.

We have a proven track record of streamlining operations and helping clients reduce time and costs with our turnkey metal stamping services. Our in-house value-added services include powder coating, packaging, and inventory management for metal stamped components and assemblies. This adds more efficiency for our customers and allows us to save both time and money.

Turnkey metal stamping solutions are a strategic way to streamline production and gain a competitive edge. Get in touch with our team to learn how HTT can transform your manufacturing process and maximize efficiency.