Most people only see the final metal stamped part. What they don’t see is the precision, planning, and expertise required to produce that part consistently at a high quality. The metal stamping process is complex and requires expertise. Let’s go behind the scenes with our metal stamping experts at HTT to show how quality is engineered into every stage of the turnkey process, helping customers avoid rework, reduce waste, and accelerate production timelines. At HTT, our turnkey model means that quality, efficiency, and cost savings are built into our metal stamping process. Let’s dive in.

Building Quality from Start to Finish

We go beyond quality control. It’s embedded into every decision from design to delivery, which has an immense impact for our customers. Our upfront design and early engineering consultations optimize part design and allow experts to catch potential issues before tooling begins. This allows us to avoid costly redesigns, move to production faster, and minimize material waste.

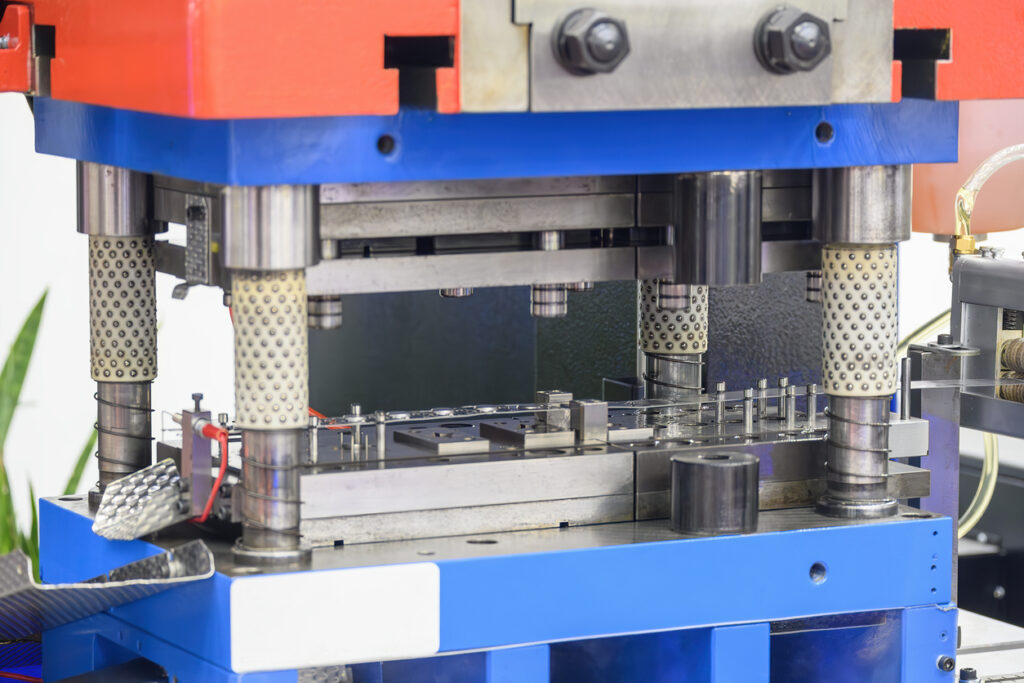

In addition, HTT’s in-house tooling expertise allows us to create precise, consistent parts efficiently. With our integrated production processes, metal selection, press selection and automation are tailored to each part. Our real-time quality assurance involves thorough inspections, end-of-line validation, and more, which results in early defect detection and less reworks. In-house secondary operations like coating, welding, and assembly result in reduced vendor-related issues and shorter lead times.

How Our Turnkey Model Saves You Time, Money, and Headaches

With fewer vendors, you can expect simpler project management. That means one point of contact and one timeline, and integrated processes result in more efficiency. Expect less downtime because there are no gaps between design, tooling, and production. You’ll also experience greater cost predictability as early planning and in-house control reduces unexpected expenses. At HTT, our turnkey approach also results in enhanced quality.

Recently we partnered with a food processing company and conducted early design consultations to improve the quality and consistency of production. Our customer was experiencing challenges with an outside vendor. Products were warping during the heat-treating process, causing dimensional changes.

We helped to isolate the root cause with our outsourcing partner to drive a better yield rate. We collaborated on the blade design and implemented proposed modifications to strengthen features in the finished tool and identify improvements in part stagings, orientations, and furnace sizes. Our team-based approach resulted in an 80% decrease in part fallout. We maintained close relationships with our suppliers, leveraging our partnerships to solve problems and create easier processes for the customer.

At HTT, quality is engineered into every step by experienced hands and proven processes. Connect with our team today to see how we can elevate your project.