Progressive die stamping is a powerful asset for product manufacturers needing high-quality, low-cost custom metal parts. With this service, you can achieve quality custom parts, created to highly complex standards and completed in faster timelines. This can help save you time and money while ensuring that your finished products will match the precise specifications of their ultimate application.

With its lower production cost and fast lead times, it offers an array of advantages and is capable of producing custom metal parts in the sizes and shapes that you need. Learn more about progressive die stamping and its benefits, and why HTT is the ideal partner to work with for your next project.

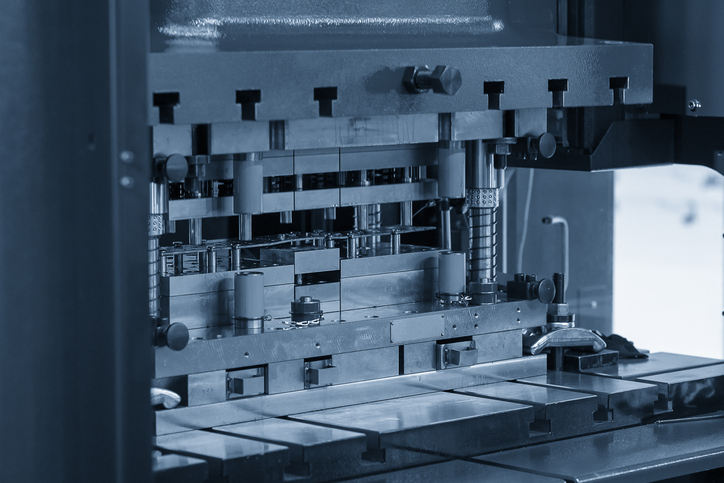

Understanding Progressive Die Process

In the progressive die process, a piece of metal works through a series of services — from bending to punching and more — to satisfy the unique needs of a customer. Next, the part is cut from that metal piece, serving as the final product. This process allows for designs both simple and complex, delivering enhanced versatility of the parts you can create.

The progressive die stamping process is also compatible with a wide range of material types and sizes. From aluminum to stainless steel, carbon steel, brass, and other coated or exotic materials, you have many options to customize your part to your ideal needs. Where some applications may require a metal that can withstand a certain temperature, other projects may require a metal part that delivers a specific strength. Progressive die stamping ensures that your finished project will be produced in the material best suited to its finished application.

3 Key Advantages of Progressive Die Stamping

Versatility

The progressive die stamping process allows for enhanced versatility in the types of pieces that you can create. Whether you require simple metal pieces or a highly complex design, this manufacturing method is ideal for both. You also have enhanced customization options for the metal materials used for your part and your part’s thickness. At HTT, we are capable of producing high-quality parts with thicknesses ranging from .002” to .375”.

Not sure what thickness or metal material is right for your project? With the right progressive die stamping partner on your side, you can count on expert support in determining the best fit for your budget and specifications to enjoy maximum performance and functionality at the lowest price.

Fast Lead Times

Progressive die stamping is known for its impressive speed to impact. This process was designed for efficiency. When you work with the right team, you can count on short lead times, whether you require Medium or high volumes of products. This gets you to market faster and pushes your project forward without delay.

A full-service progressive die stamping partner can also handle the secondary operations you require in-house, such as welding, powder coating and assembly. Turnkey manufacturing can save vital time in your project, allowing you to finish under one roof and move on to the next stage even faster. When you work with a turnkey partner like HTT, you can speed your project up even more and enjoy higher-quality products as a result.

At HTT, we understand that keeping production timelines as short as possible without compromising quality is a key priority for many of our customers. We have found our processes to deliver more efficient and expert support so we can keep your lead time slow and deliver the best quality products as a result.

Low Cost

Progressive die stamping offers cost-saving benefits that support your bottom line while ensuring you enjoy custom products made to the highest quality standards. Because it offers a quick setup, speedy production, and a high level of repeatability, this method offers lower costs per part. This can make a powerful price difference in medium and high-volume production.

It also produces less scrap material and allows you to minimize waste and wasted expenses. When you choose a smarter metal manufacturing method like progressive die stamping, you can count on our team to work as conservatively as possible with the materials. This ensures you get the number of high-quality parts you need exactly when you need them while minimizing waste.

Work with HTT for Your Progressive Die Stamping Needs Today

At HTT, we are committed to serving our customers with turnkey progressive die stamping services that maximize the value of our partnership and ensure that your needs are met at every stage. Whether you require prototyping support, fabrication, progressive die stamping, or a secondary service like powder coating, we are here to help. We serve a variety of industries with high-quality metal stamping, including the automotive sector, medical, and more.

Founded in 1985, our team has grown from only 10 employees to more than 130, each committed to executing exceptional quality projects for our customers. Our progressive die stamping services are backed by a strong quality commitment showcased through our industry certifications. When you turn to our team for expert progressive die stamping, you can enjoy quality custom metal parts that match your complex requirements and are completed in the timeline you require.

For world-class progressive die stamping from an engineering-driven team that truly cares about your needs, contact us today.