At HTT, our team of engineers, designers and machinists help you create the metal components you can count on.

Get Started NowSince 1982, some of the nation’s most celebrated automotive, metal stampings for gas engines, diesel engines, and appliances. Drawing on over 130 employees and 161,000 square foot of production space, we’re masters at manipulating carbon steel, brass, copper, beryllium, stainless steel and aluminum—and have a variety of certifications to prove it.

HTT Quality Policy - The Employees of HTT/World Stamping will consistently produce Products and provide Customer Service that meets or exceeds our customer's requirements. This will be done in an atmosphere that promotes employee involvement and continuous improvement in the organization.

From Design to Production

Cutting-Edge Technology

Engineering–Driven Team

Unmatched Project Management

Our team of creative and calculated engineers takes a concierge approach to executing your project through our entire process, from initial print to final production. We use comprehensive, cross functional project management to mitigate risks and increase predictability to ensure new project launch success.

Digital Wireframe

Our team begins each project as a CAD model to ensure proper dimensions.

Formability Testing

Using advanced software, we then determine how to best utilize materials in our presses to deliver the best product.

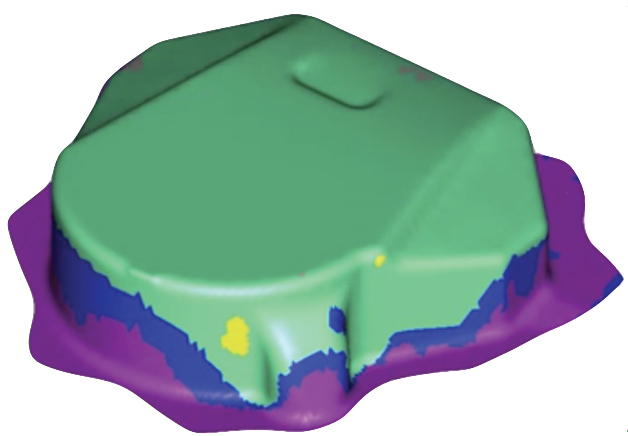

3D Render

A 3D mockup is then created as a final for accuracy and precision.

Although we specialize in automotive, plumbing and commercial applications, we’ve worked with companies in nearly every industry.

Our more than 200 employees are the best at what they do, but only because we are—all of us—constantly looking for ways to improve ourselves and our workplace. For nearly 40 years, our emphasis on transparency and being real with each other has helped us grow as a company and as individuals—and we’re always looking for new talent to grow with us.